Vacuum services tend to be forgotten about but are essential for anaesthetics. We use two systems, one providing relatively low flow rates but with high suction (medical vacuum or suction) and one with very high flow-rates but low suction pressures (AGSS or scavenging).

This can be provided by local systems or via a piped network. Local systems include those run by electrical pumps or gas-driven (Venturi). Both can work well in providing highly portable systems, although battery operated, electric pumps have generally taken over from gas-driven systems.

Local battery and venturi suction devices.

Although showing small, local suction devices, Figure 1 demonstrates the elements required of any suction system

- A power source (electrical, pneumatic or even manual

- A device to generate the suction (pump, venturi etc.)

- A filer to protect the suction apparatus from contamination

- A receiver

- A protective device which shuts off the suction when the receiver is full (often a float valve).

- A length of non-collapsible tubing

For anaesthetic use, the system should be able to cope with flow rates of 35l/min (air) and generate pressures of -80kPa (600mmHg).

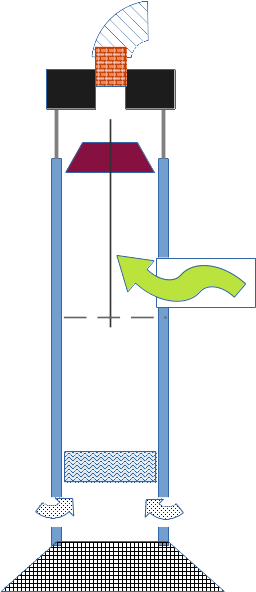

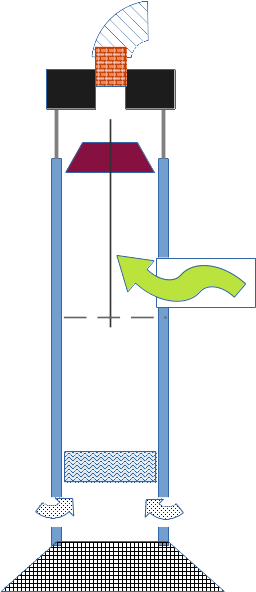

A scavenging system has the following components:

- A collecting system which harvests wastes gases from the breathing system and delivers them to the transfer system. This may be as simple as a shroud surrounding an APL valve.

- A Transfer system - moves the waste gas from the collecting system to the recveiving system. This is a wide-bore (generally 30mm) hose.

- A receiving system

- A disposal system

The above appears very obvious, but practical designs are complicated by the need to be able to cope with widely varying flow-rates and to fail-safe in the event of systems failures or occlusion of the pipework.

One design which has been widely used is shown below.

The 'float' becomes visible when the system is operating normally (e.g. flows of around 120l/min). In the event of excessive scavenging pressures, then air is entrained from the open end of the system. Alternatively, in the event of a scavenging failure, waste gas can be discharged via the open end, protecting the patient from excessive back-pressure.

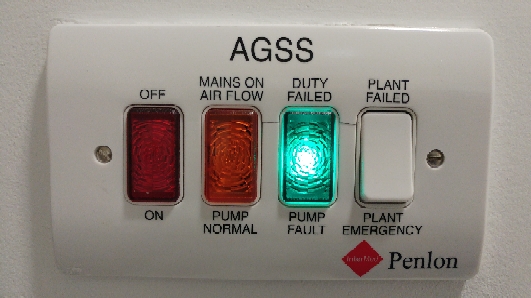

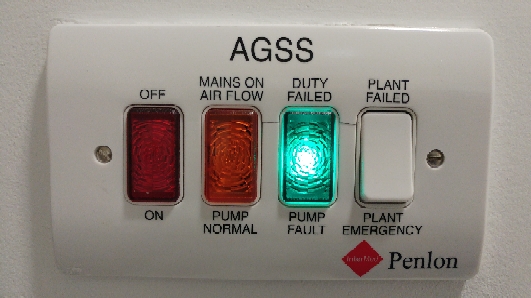

Active systems are expensive to run (energy intensive). As a result, it is not uncommon for there to be local controls (fig. - although here, something might not be quite correct. N.B. The company named on the plate were not responsible for the installation !) allowing them to be switch on and off as needed. This makes the checking the scanvenging an important component of the machine check.

A local AGSS control unit - albeit by an incompetent installer.

Early systems were 'passive' allowing waste anaesthetic gases to be vented to the outside. These systems contained no pumps, but the Venturi effect of any wind might be harnessed to assist with removal of the gases. As might be imagined, the efficiency was unpredictable and these systems should no longer be in use.